More About Material Test Lab

Wiki Article

Some Ideas on Material Test Lab You Need To Know

Table of ContentsRumored Buzz on Material Test LabThe Material Test Lab Ideas

When checking out a Material Examination Record( MTR), the material's physical as well as chemical make-up can be validated despite the document's origin. The heat number ought to be physically existing and identifiable on the product's surface. This number is after that compared to the associated MTR to make sure both match. Basic surface and also edge dimensions

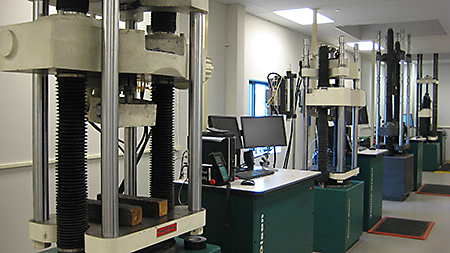

will certainly further confirm this material adapts job requirements based on physical measurements as well as density. More examination will require the individual (s) to reference the ASME/ ASTM/ EN standards area applicable to their project material requirements. Provided that the evaluation of these three components yield sufficient results, the MTR can after that be stored, digitized, as well as appointed to the material, which is then gotten rid of to get in the next stage of the production procedure. The American Society of Mechanical Engineers (ASME) is among the earliest standards-developing organizations in America. ASME criteria are translated right into dozens of languages as well as are made use of in greater than 140 nations. The organization has more than 100,000 members and trains more than 5,000 people yearly. Formerly recognized as the American Culture for Testing and Materials, ASTM International has actually grown right into an international designer of voluntary consensus requirements. material test lab. According to the agreed-upon occupants of the standards organizations, an EN (European Requirement)" brings with it the responsibility to be carried out at the nationwide degree by being provided the condition of a nationwide requirement and also by the withdrawal of any conflicting nationwide criterion". Therefore, a European Standard( EN )becomes a nationwide standard in each of the 34 member countries . That is unless legislations and also guidelines or else impose criteria compliance. Specifications have a place in simply regarding every organization read this post here and also procedure human beings take useful link part in daily. Standards streamline and safely facilitate various elements of day-to-day life. Standardization makes sure that items, services, as well as methods are proper for their intended use. It makes sure that products as well as systems are compatible as well as interoperable, too. Material screening has actually ended up being an integral stage in mostly all kinds of sectors for guaranteeing its quality as well as safety. It is mainly important especially in the construction and cars and truck manufacturing industries since if done anything incorrectly, it can harm individuals. Thus, the need for appropriate material screening comes to be vital to protect the individuals who will be making use of the produced item. Rather of evaluating the product as a whole, it is an excellent practice to check the individual components that is making the item. Testing the products made use of for a specific item in an industry involves a degree of unique engineering. Using structural analysis it is checked just how well an equipment perform when exposed to particular variables. This is likewise the way to satisfy certain top quality criteria and also therefore ensuring product depends on par in regards to high quality. Products that undergo Product Testing, For testing, many of the sectors utilize material screening maker to assess the mechanical residential properties of products and also parts. Numerous essential parameters like stress, compression, flexure, torsion as well as hardness are taken into consideration while valuing the materials as well as grading them. With the Wood screening, it can read be able to identify the strength and also deformation residential properties of timber. For testing the timber, Bend testing is particularly useful to evaluate its strength since it is often made use of in the form of light beams where resistance to bending is an essential parameter. Furthermore, Fixtures are likewise evaluated to measure their stamina and also endurance and also these material screening results assists in.

Report this wiki page